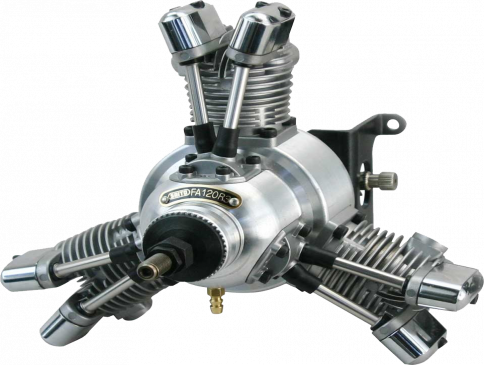

SAITO FA-120R3

As Break-in is an important procedure to pull out the maximum performance of the engine, it must be cautiously implemented.

1. After filling up the fuel tank, start the engine as described in the above section F. After starting the engine use the throttle stick to open the throttle valve to about half open. Adjust the main needle while observing tachometer, exhaust oil concentration and exhaust concentration from the breather, to run the engine at 5,000rpm or lower speed in rich condition for full tank fuel consumption. (Run the engine with plugs powered as required.)

2. Next adjust the main needle and throttle valve opening to run the engine in rich fuel condition at 7,000 – 8,000 rpm for full tank fuel consumption. (In this stage also observe tachometer reading, exhaust oil concentration and exhaust concentration from the breather.)

3. Next fully open the throttle valve and adjust the main needle to run the engine at approximately 9,000 rpm for full tank fuel consumption.

4. Finally adjust the main needle to run the engine at peak speed and less speed (richer) alternately. When the engine comes to run at a peak speed stably, ground break-in has been completed for the time being. Now adjust valve clearance by following procedure of maintenance described later. Then adjust carburetor according to the next article and make test flights at less speed around ten times to complete break-in. (Thereafter make flights at less speed, to prolong engine life.)

Unique features of SAITO FA-120R3:

1. Optimum for small-size scaled airplane

2. Low vibration (assured by constant-interval explosion)

3. Real sound of the exhaust.

4. The engine is designed to equalize fuel mixture and minimize misfire due to insufficient distributing at idling by means of special port type intake manifold originally developed by SAITO.

5. Cylinder head: Improved semi-spherical combustion chamber assures better combustion efficiency and volumetric efficiency.

6. Cylinder: The aluminum cylinder is directly hard-chrome plated on its inner surface without installing liners to reduce weight and increase durability. The monolithic structure of cylinder head and cylinder prevents distortion and improves cooling efficiency. • Piston: The piston is made of high silicon content aluminum and attached with a compression ring to heighten engine performance.

7. Crankshaft: Has a forged solid construction made of chrome molybdenum steel, and supported by two ball bearings.

8. Cam: Features high cam providing longer maximum lift time.

9. Carburetor: High-performance of slow throttling type.

10. Propeller nut: designed to have double nuts preventing loosening and fall-off for the safety.

Specifications:

* Bore 22.4mm x 3

* Weight Approx. 890g (with mufflers)

* Propeller Standard APC13"×8"-14"×6"

* Stroke 16.2mm×3

* Practical Speed 1,800-10,000rpm

* max range on the ground: 8,500-9,500rpm

* Stroke volume 19.18cc

* Static thrust Approx. 3.5kgf (by APC14"×6"prop)

* Fuel flow 24cc/min (At full throttle,

* Fuel of synthetic oil with 15% of nitro content,APC13"×6"prop at approx 9,400rpm)

Fuel flow varies depends upon prop load. More fuel flow with larger load and less fuel flow with smaller load

| Weight: | 1.4000 |

USD

USD